Volclay Swelltite

- Features

- Description

- Performance

- Projects

- Downloads

Features

Key Features

Superior waterproofing technology, SWELLTITE waterproofing system is a proven waterproofing solution for blocking water with over 50 million square feet installed across the planet over the last 20 years.

Fast and Easy to Install:

- SWELLTITE is comprised of a thick layer of sodium bentonite compound that’s bonded between a tough geomembrane liner and a clear poly siliconized release liner to provide flexibility.

- SWELLTITE comes ready to install allowing for faster and easy installation speeding up the construction process and can be applied to new or existing structures.

- SWELLTITE can be applied to a damp or wet surface, no priming required.

- Unlike most membranes, SWELLTITE does not require a dry substrate to be installed.

- No curing time means it can be applied to green concrete.

DURABLE AND SELF-SEALING:

SWELLTITE is extremely durable and self-sealing—there are no worries about the inevitable small cuts and punctures that always occur on construction sites.

HOW DOES IT WORK:

SWELLTITE features a virtually zero VOC waterproofing membrane composite. It’s comprised of a thick layer of sodium bentonite compound that’s bonded between a tough geomembrane liner and a clear poly siliconized release liner.

Whether a structure is under continuous or intermittent hydrostatic pressure, SWELLTITE is a proven and reliable barrier against water. Bonding an active bentonite layer between tough, puncture-resistant geomembrane layers, SWELLTITE combines both passive and active barriers to substantially reduce the possibility for leaks.

IDEAL MEMBRANE FOR:

- Masonry block walls

- Erected concrete walls

- Precast panels

- Insitupoured walls

- Ground beams

- Internal leaks when confinement can be achieved

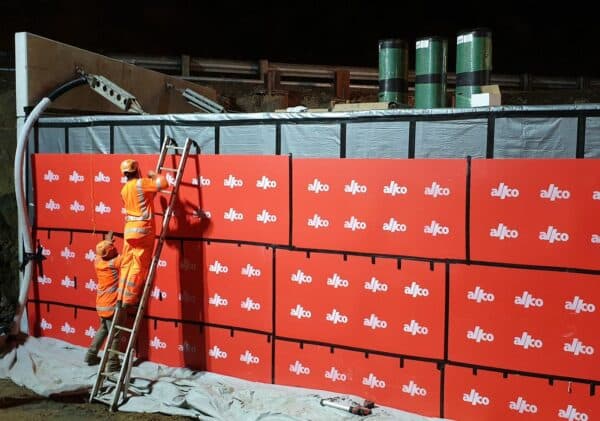

Proven quality and ease of installation have made SWELLTITE a market leader in the New Zealand waterproofing industry. For more than 20 years SWELLTITE has been installed in New Zealand on projects such as backfilled foundation walls and cut-and-cover tunnels.

SWELLTITE® Composite Bentonite Waterproofing System offers superior performance by combining the active waterproofing benefits of sodium bentonite with the strength and durability of a thick geomembrane liner. Unlike other membrane systems that require precise installation, SWELLTITE’s reactive bentonite compound can expand to seal small punctures in the membrane. SWELLTITE works by forming a continuous membrane upon hydration with water or vapour. When confined under pressure, the swell is controlled, forming a dense, positive seal against the concrete.

APPLICATIONS

Swelltite is designed for waterproofing below-grade vertical and horizontal structural surfaces, as well as, above grade split-slab construction used with plaza areas, parking garages and sports stadiums. Swelltite is excellent for:

- Below-grade masonry block walls

- Cut & Cover Tunnels

- Masonry Block Foundation Walls

- Concrete Foundation Walls

- Earth-covered Structures

- B2 DURABILITY: Performance B2.3.1 (a) not less than 50 years.

- E2 EXTERNAL MOISTURE: Performance E2.3.3.

- F2 HAZARDOUS BUILDING MATERIALS: Performance F2.3.1. The Volclay® Waterproofing System meets this requirement and will not present a health hazard to people.

- BRANZ and BBA Appraised

The Volclay Waterproofing System is an approved Alternative Solution in terms of New Zealand Building Code compliance.

ROLL SIZE & PACKAGING:

Volclay Swelltite is supplied in 1.0 m x 11.5 m rolls for 11.5 m² per roll.

LIMITATIONS

- Swelltite should only be installed after proper substrate preparation has been completed and is suitable to receive the waterproofing system.

- Concrete work should use conventional cast-in-place forms that produce a smooth surface.

- Do not use stay-in-place concrete forming; use removable forming products only.

- Do not use product without proper backfill or topping slab confinement.

- Swelltite is not designed for unconfined above-grade waterproofing applications or subsurface applications that do not provide full confinement coverage.

- Do not install Swelltite on horizontal plaza deck applications that utilize pavers placed on pedestals. Swelltite is not designed to waterproof expansion joints.

- Do not install Swelltite in standing water or during precipitation.

- If ground water contains strong acids, alkalis or is of conductivity of 2,500 µmhos or greater, submit water samples to the manufacturer for compatibility testing.

- Consult Allco for special installation guidelines that apply to shotcrete and precast concrete construction.

- Install Swelltite only in dry weather. Installation should not proceed when work areas are flooded or excessively wet, nor when rain can be reasonably anticipated before Swelltite can be properly covered.

139 Greys Ave – Te Mātāwai Kaianga Ora Project

Te Mātāwai is a pivotal residential development in the heart of Auckland CBD, part of Kāinga Ora redevelopment.

Read More

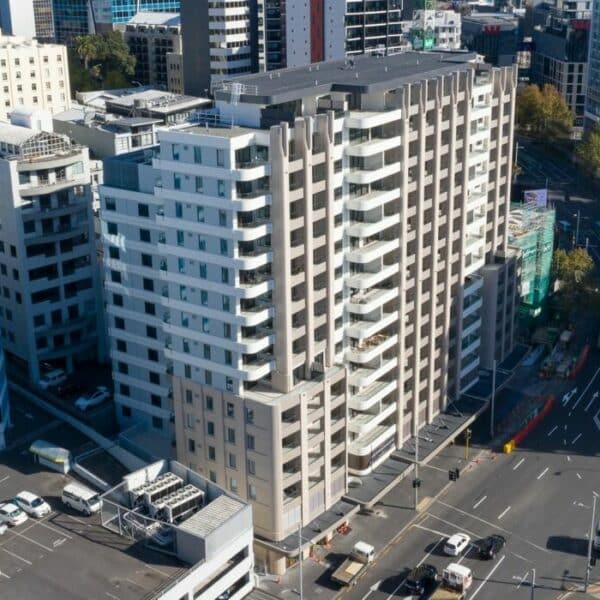

Antipodean Apartments

Recently completed, this substantial inner-city residential development encompasses 160 apartments over 14 levels in the vibrant heart of Auckland’s CBD.

Read More

Aria Bay Retirement Village

Aria Bay is an innovative residential retirement village situated in the heart of Browns Bay.

Read More

ASB Building – North Wharf

In the ASB project, Casali features across the roof expanse of buildings 22 and 23

Read More

Auckland Art Gallery

The project involved a significant amount of civil works, with retention piling, soil nails and ground anchors used to allow excavation and construction of new basement levels between the heritage buildings.

Read More

Auckland Grammar School Library

The Auckland Grammar School Library required a robust and watertight tanking solution to withstand the physical demands of the site and ensure structural longevity.

Read More

Auckland War Memorial Museum

The rear Southern courtyard, built in 1960, provided the space for six new floors. The courtyard was excavated to a depth of 12 metres to allow two basement levels.

Read More

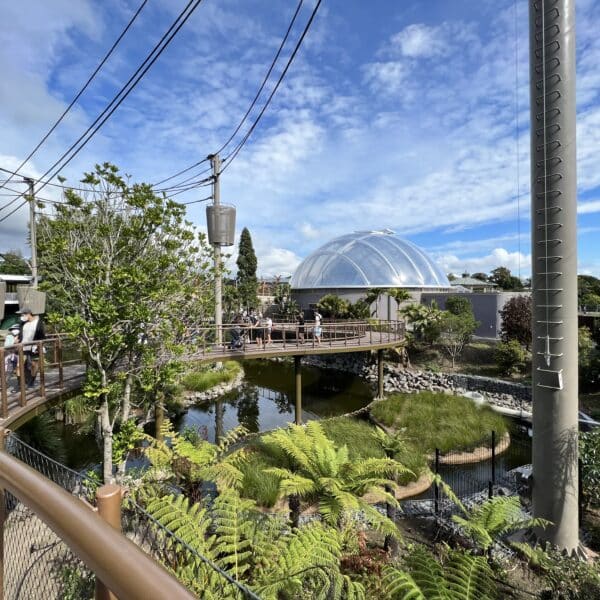

Auckland Zoo – East Asia Precinct

Auckland Zoo is the biggest Zoo in New Zealand. This project was apart of the Zoo’s 10-year re-development plan attempting to transform the zoo.

Read More

Bethlehem Medical Centre

Bethlehem Medical Centre located on Auckland's North Shore, utalised Allco's Volclay Product Range.

Read More